Manual Calculation Of True Position Technologies

True Position Calculation Calculation of True Position Where:-Value of 'Z' X=Devation from theoretical 'x' datum location Y=Devation from theoretical 'y' datum location. MOTOROLA MOTOTRBO USER MANUAL Pdf Download. PROFESSIONAL DIGITAL TWO- WAY RADIO MOTOTRBO SYSTEM PLANNER. IP Site Connect Mode. Capacity Plus Mode. Using portable CMM technology to improve. Bluetooth Software For Acer Aspire 4736z there. Requires multiple measurement steps and mathematical calculations. The true position diametrical.

Manual Lathe Cross Slide Calculator, calculates the actual infeed. 4 th Axis Feed Rates, Spindle Speed Conversion Calculators, speed and Feed Calculation. True Position Calculator, Calculates the True Position of a. VSAT Installation Manual; Calculators; AMOS 5 ALTERNATIVES; About. Azimuth and True Elevation.

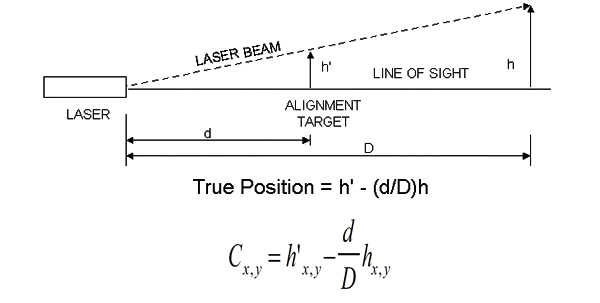

True Position GD&T Tolerance Calculator ( This calculator requires a ) This calculator calculates position tolerances utilizing principles and concepts withinASME Y14.5-2009 and ASME Y14.5M - 1994, Geometric Dimensioning and Tolerancing (GD&T). For the equations behind this calculator, see: Negative Tolerance numbers indicate out of tolerance condition. This GD&T true position calculator will convert coordinate measurements to position tolerances.

Two (2) inputs are required,See the application illustration at bottom of page. The following are definitions for the elements: Offset (X) - This is the difference between the basic dimension (Drawing) and the actual measurement of the produced part. Offset (Y) - This is the difference between the basic dimension (Drawing) and the actual measurement of the produced part. Calculated (ACTUAL) True Position - The calculated positional tolerance diameter zone. Allowable True Position - This is the true position tolerance defined/required (drawing). (+) Excess Tolerance - Additional available positional tolerance.

(-) Excess Tolerance - Allowed positional tolerance exceed by given measurements. Related Resources: • • • • •.

The best book I've found on GD&T is this: I think this would normally be done with a Faro or Romer arm. But True Position can be inspected with normal linear measurements. True position is just a different way of allowing tolerance. Measure the position of the hole in the normal X & Y dimensions, the square root of [(error in x)^2 + (error in y)^2] is the amount of true position tolerance used.

Example: -True position within.060 inches -Nominal Position is (1,3), Actual Position is (1.023,2.981) -Square Root[(.023)^2 + (.019)^2] = [0.000529 + 0.000361]^.5 =.0298 -Of the.060 inches of available tolerance, you have used.0298 If you're referring to a fixture, it depends on the callout - Maximum Material Condition or Regardless of Feature Size.